featured industry Solution

About Us

We are leading manufacturer of construction materials like AAC blocks in Southern Maharashtra. Our Managing Director Mr. Sopan D. Patil has 32 years of experience in construction sector. Under his guidance to fulfill the demands of real estate and construction sector, we have entered this sector with advanced technology and a team of dedicated professionals.

After a proper research and development we have come up with the product “BUILD LIGHT” AAC blocks.

We are honest in quality and believe in giving the best to society.

about Us

Build Light AAC Block

SS Conmat is Maharashtra’s leading manufacturer of Autoclaved Aerated Concrete Blocks: an amazingly Innovative and Green Building Material. What makes it superior is its incredible lightweight and insulation properties. About 1/3rd the density of clay brick, can be laid much quicker, saving time and building costs. Being more resilient to damage helps reduce wastage during transportation. These blocks offer effective & practical solutions for the current building regulations and are manufactured using the latest technologies at India’s most advanced AAC facilities located in Kolhapur.

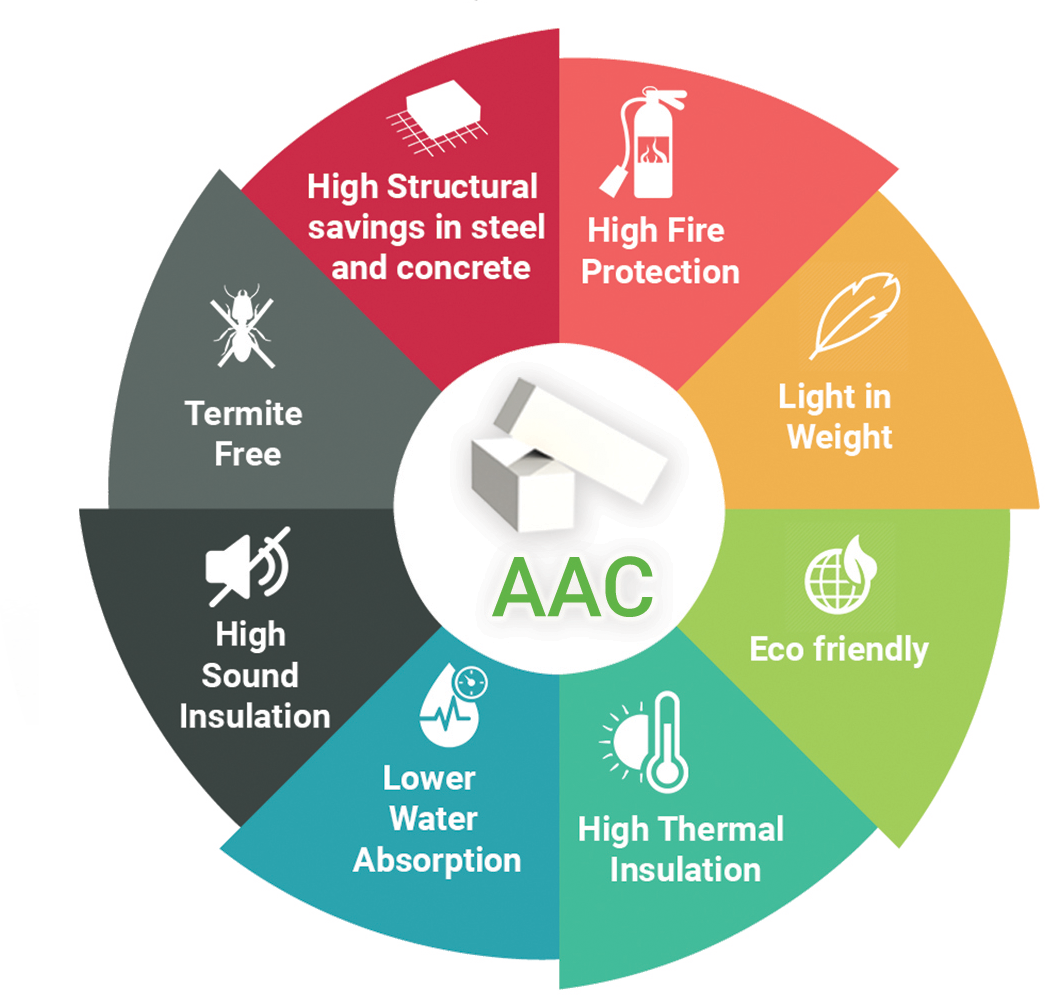

Key Features

Unique & Excellent type of building blocks made with materials which can with stands heat , fire and is sound resistant

- Earth Quake Resistant

- Pest & Termite Resistant

- All Weather Proof

- Sound Proof & Fire Resistant

- Quick & Easy Installation

- Dimensional Accuracy for Perfect Fit

- Adjustable & Light in Weight

- Ribbed Face

- Cost Effective & Durable

- Built Strong & to Last Long

what we do

WHY CHOOSE BUILDLIGHT

We are leading manufacturer of Autoclaved Aerated Concrete (AAC) blocks in Maharashtra. AAC blocks are also known as Fly ash / Lightweight Brick/Block. Buildlite itself on maintaining the highest level of customer service and support.

We are founded with the vision of helping people build their homes in a better, faster & cheaper way by the use of innovative construction technologies. We offer blocks that are durable and eco-friendly construction materials.

Lightweight AAC block’s improved thermal efficiency reduces the heating and cooling cost in buildings. Lightweight blocks save cost and energy in transportation and labor expenses.

our features

Applications of AAC Blocks

AAC is used as concrete masonry units. It is particularly economical in large-scale projects and is widely used in industrial and civil construction. These can be used for walls, floors and roofs. AAC products can be divided into AAC blocks and AAC panes. Its application includes:

- Construction of dwellings and businesses.

- External walls because of their outstanding insulation properties.

- Multi-store construction and it is quite viable for even 5-storey constructions.

- Entire residential areas are built using autoclaved aerated concrete

- A very big reason for this is the ease of application, even for the non-professional, thus enabling a high level of personal contribution and resulting in a reduction of building costs.

- Used for internal walls as walls are so level, they can be finished with a very thin coat of plaster (3 – 5 mm).

- Can be used to quickly create kitchen surfaces. And also easy to remove without damage to the surroundings.

Technical Comparison

| Particulars | Conventional Red Bricks | AAC Bricks |

|---|---|---|

| Strength | 25 - 30 kg/cm2 | 35 - 45 kg/cm2 |

| Shapes & size | Non uniform & irregular | Regular & uniform |

| Water absorption | 40 - 45% | 15 – 20 % |

| Breakage / Wastage | 8 – 10 % | Nill – 0.5 % |

| Mortar Consumption | High | Less |

| Density | 1500 – 1700 kg/m3 | Upto 700 kg/m3 |

| No. of bricks/cubic m | 565 nos [9 X 4 X 3 inch ] | 67 nos [25 X 9.6 X 4 inch] |

| Mortar joint thickness | 15 – 18 mm | 3 – 5 mm |

| Plaster Thickness | 15 – 20 mm | 8 – 10 mm |

Technical Specification

| Property | Units | Sizes |

|---|---|---|

| Sizes | mm | 600 X 200 / 240 X Thickness |

| Thickness | mm | 50,75,100,125,150,200,225 |

| Compressive Strength | N/ mm2 | > 3 -4.5(2185) |

| Normal Dry Density | Kg/ m3 | 700 |

| Drying Shrinkage | % | 0.04 % (size of Block) |

2014

Foundation year

6000 +

Project Done

150 +

Solutions delivered

200 +

Professional Team

articles

Recent Blogs

Changing from one season to another often disrupts the schedules and routines that enable our lives to run smoothly, and the change from summer to fall is no exception.

The thermal effectiveness and energy effectiveness of a workplace can be made or broken by its windows.

Autoclaved Aerated Concrete (AAC) is a precast, foam concrete building material that is lightweight and ideal for constructing blocks-like concrete masonry units. The materials that makeup AAC products are quartz sand (SiO2 with impurities), calcined calcium sulfate, lime (CaO), cement, water.

In the contemporary world, due to the increase in building costs and rising need for skilled labour, the construction business is under constant pressure to develop new, sophisticated, and original concepts.

QUALITY SYSTEMS AND QUALITY ASSURANCE